Drawings, Design and Fabrication

Elite Engineering's CNC machine shop is located in the city of Camarillo, in southern California. We specializes in design and prototyping for mechanical parts and custom orders. We focus on small runs of one to one thousand pieces. We pride ourselves on combining quick turnaround with high-quality output while emphasizing precision, speed, and flexibility. We accept technical drawings or can create a technical drawing and have support teams to ensure you get quality CNC machined parts on time.

Xometry Network guarantees the quality of every part we manufacture. Along with thoroughly vetting the manufacturing partners we work with, every order is dimensionally and visually inspected according to The Xometry Network Standard.

Choose from our list of materials to help you select your part.

ABS

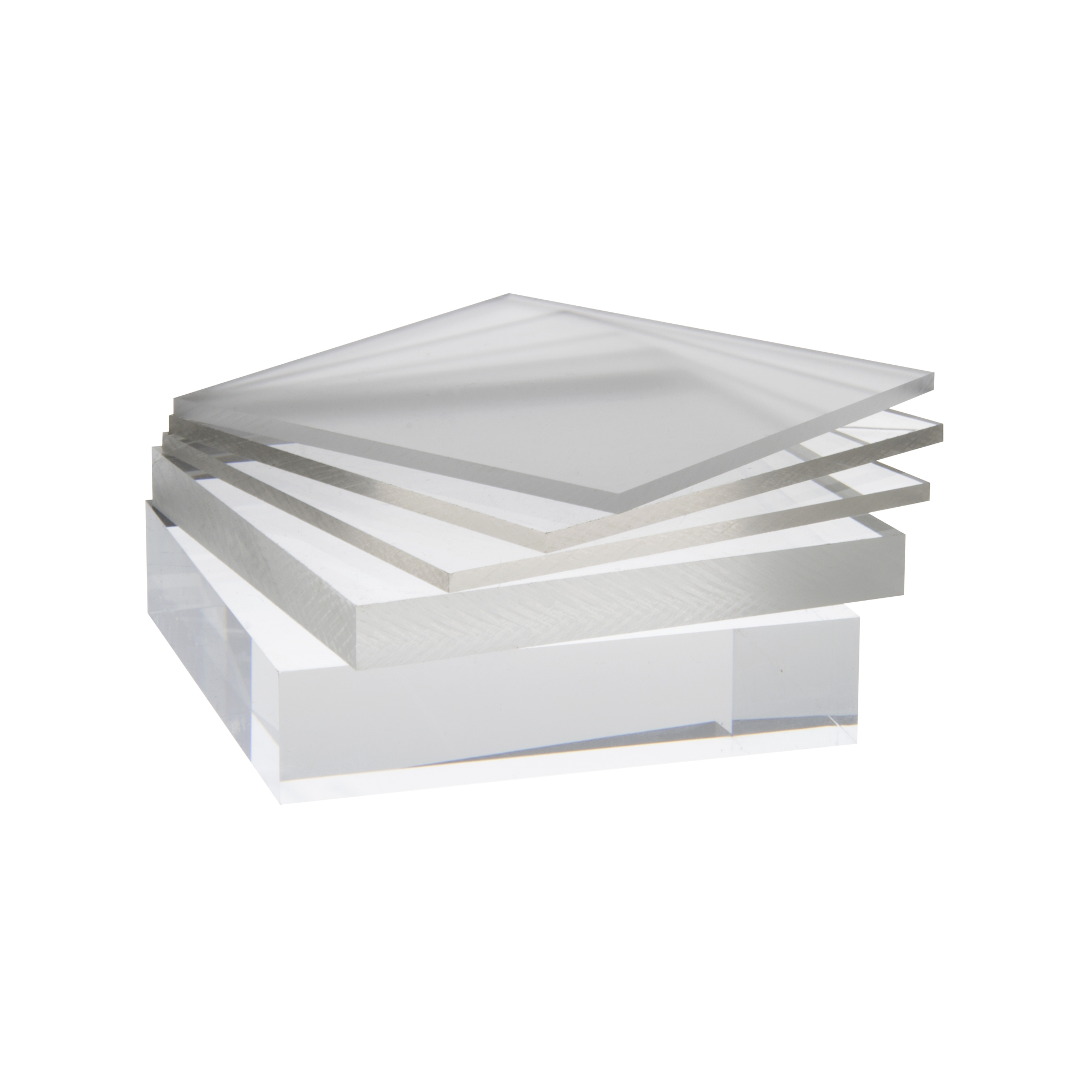

Acrylic

Aluminum

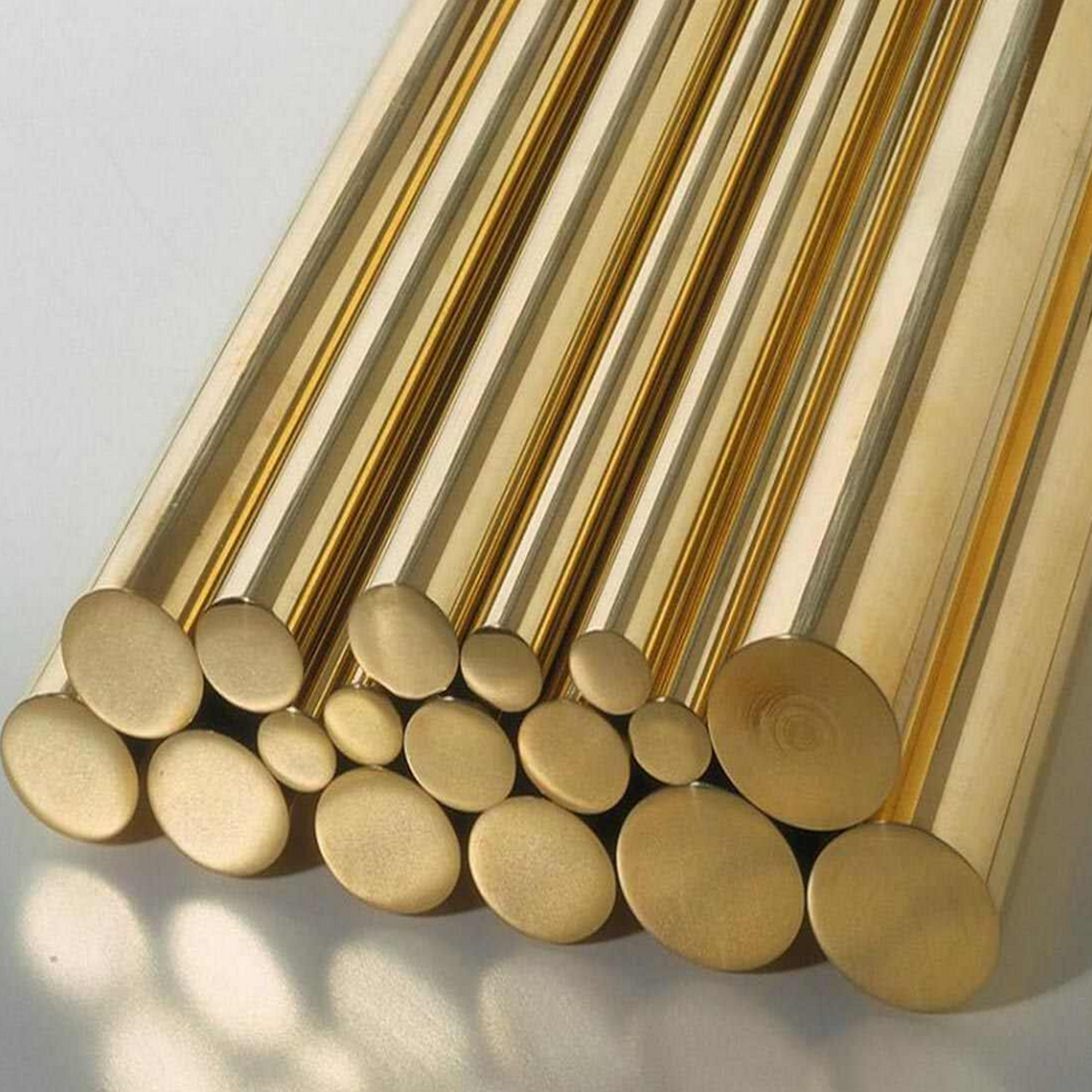

Brass

Bronze

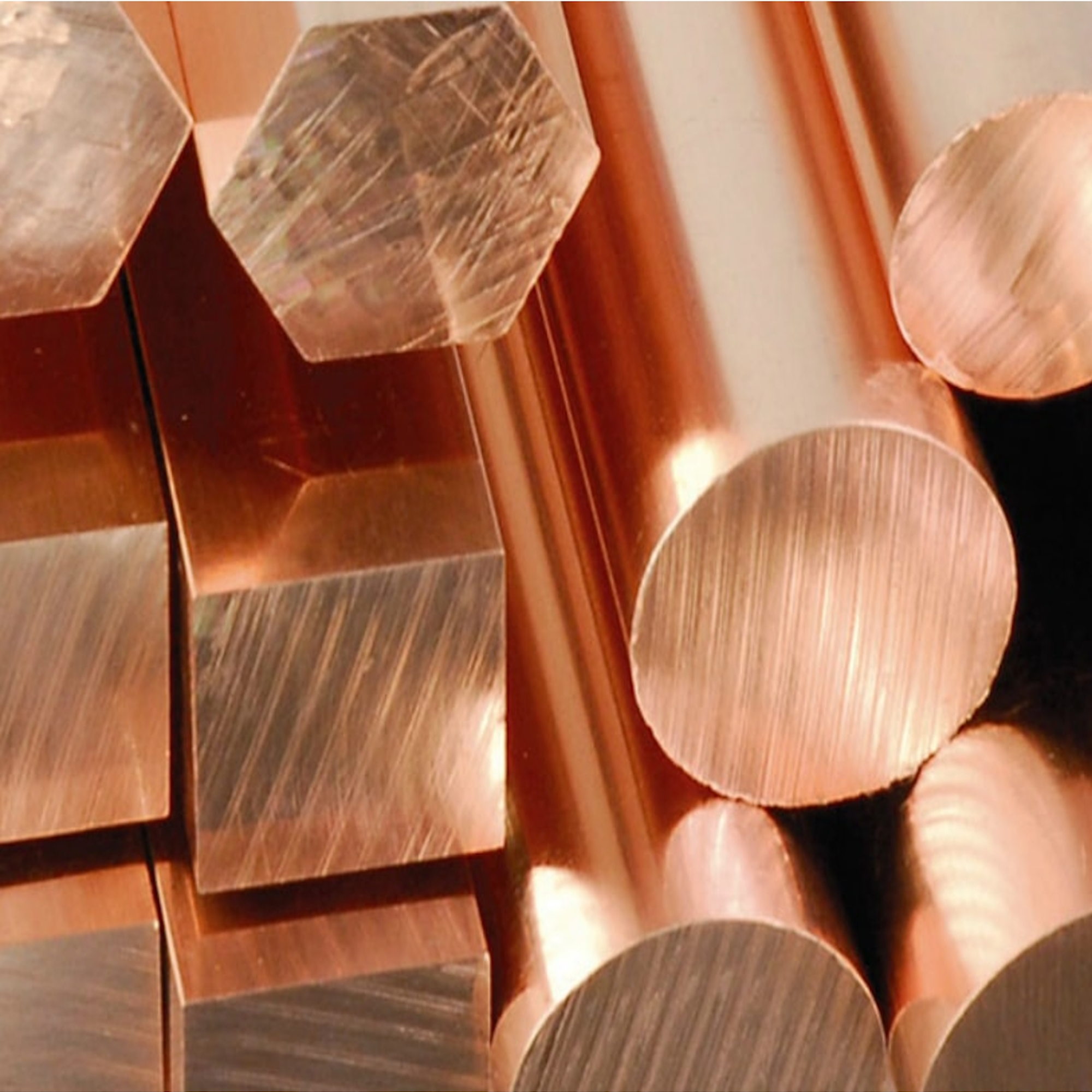

Copper

Delrin®

Garolite G-10

HDPE

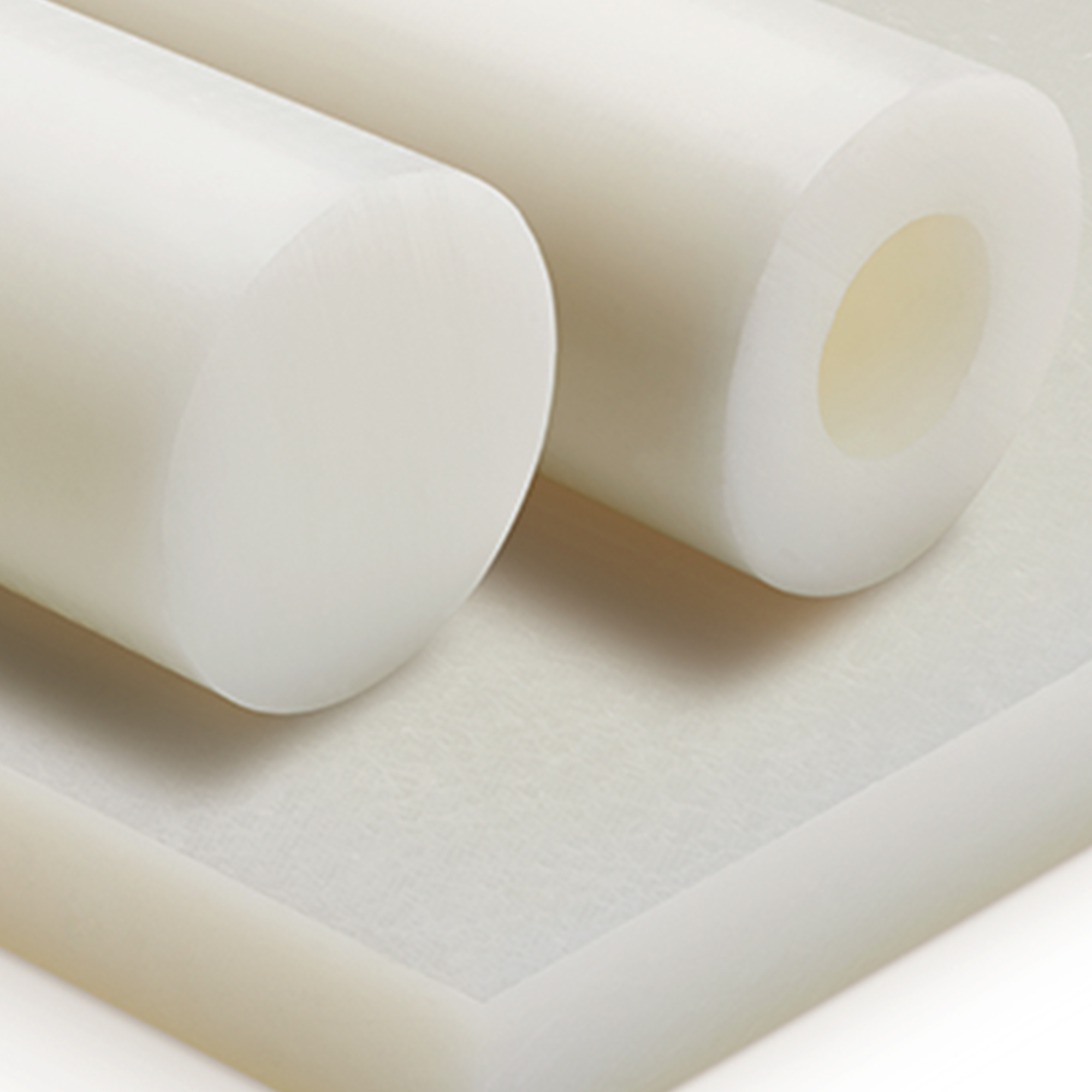

Nylon

PEEK

Polycarbonate

Polypropylene

PPS

PTFE(Teflon™)

PVC

Stainless Steel

Steel

Titanium

UHMW

Ultem

Zinc

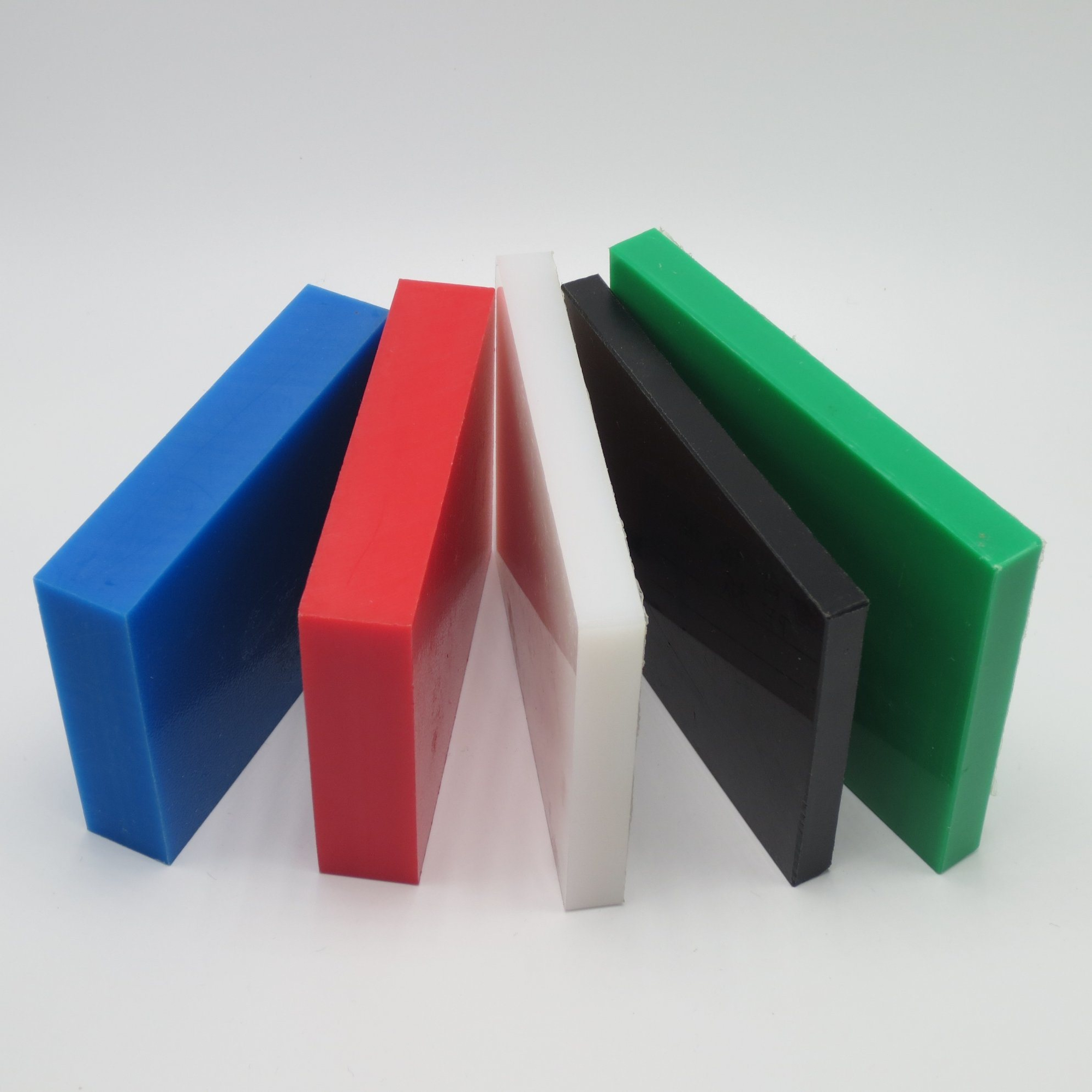

ABS is a low-cost engineering plastic widely used for pre-injection molding prototypes.

| Mill Lead Time: | *Same day available for small simple parts |

|---|---|

| Color Options: | Black, neutral matte finish |

| Material Cost: | Lowest |

| Alloys & Types: |

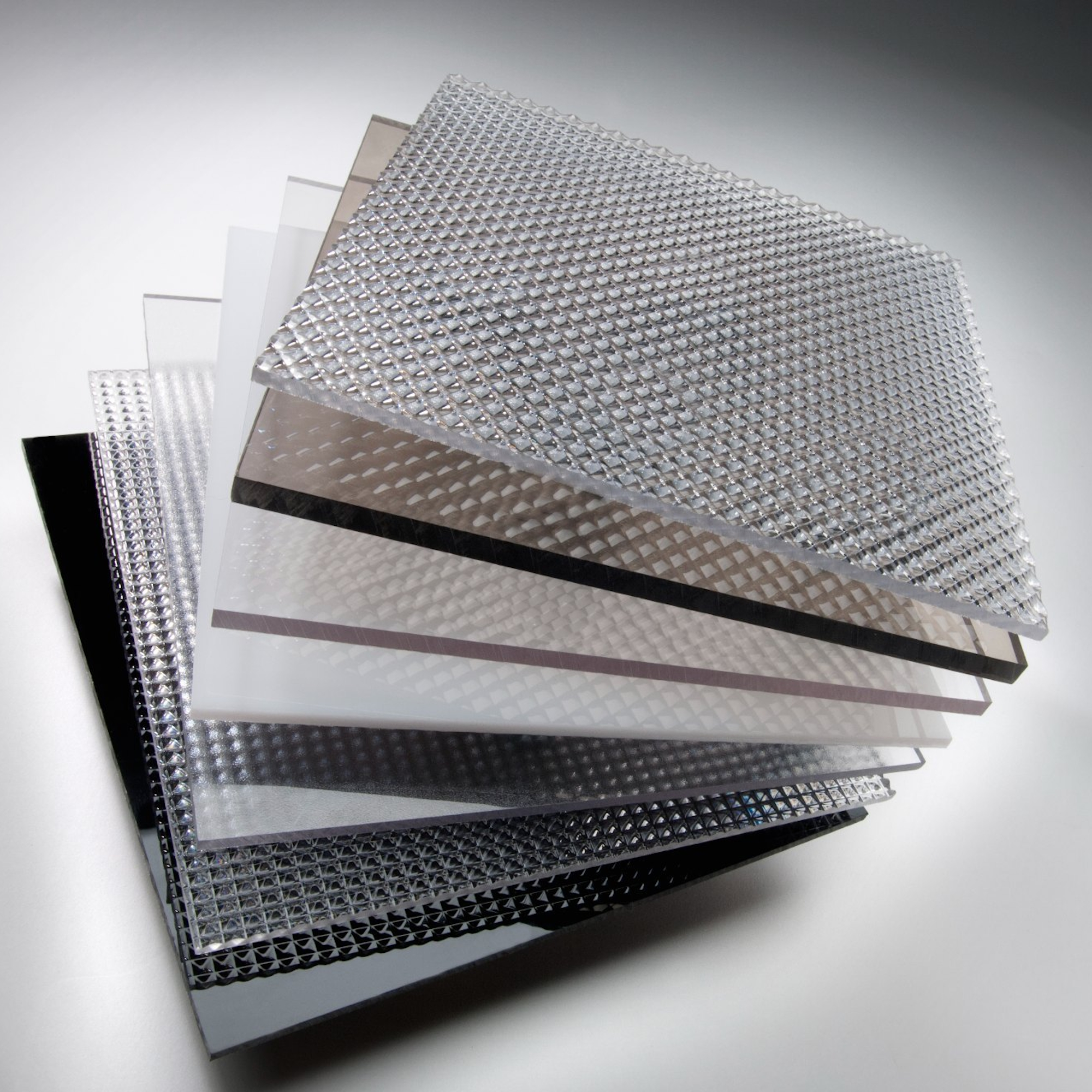

Acrylic is a scratch-resistant plastic material, often used for tanks, panels, and optical applications.

| Mill Lead Time: | As fast as 7 days |

|---|---|

| Color Options: | Optically clear, opaque |

| Material Cost: | Medium |

| Alloys & Types: |

Aluminum is one of the most commonly used metals in the world because of its excellent strength-to-weight ratio, low cost, and recyclability.

| Mill Lead Time: | *Same day available for small simple parts |

|---|---|

| Finishing Options: | Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing. |

| Material Cost: | Low |

| Alloys: | 6061-T6, 7075-T6, 7050, 2024, 5052, 6063, MIC6 |

360 Brass, also known as free machining brass, is commonly used for a variety of parts including gears, lock components, pipe fittings, and ornamental applications.

| Mill Lead Time: | As fast as 3 days |

|---|---|

| Finishing Options: | Media blasting |

| Material Cost: | Low |

| Alloys & Types: |

932 Bearing Bronze is a high strength alloy with good wear and corrosion resistance due to its tin, iron, and zinc content. In general, bronze is considered more machinable than brass due to its higher ductility and lower zinc content.

| Mill Lead Time: | As fast as 3 days |

|---|---|

| Finishing Options: | Available as-machined, media blasted, or hand-polished |

| Material Cost: | Medium |

| Alloys & Types: |

101 and 110 copper alloys offer excellent thermal and electrical conductivity, which makes them natural choices for bus bars, wire connectors, and other electrical applications.

| Mill Lead Time: | As fast as 7 days |

|---|---|

| Finishing Options: | Available as-machined, media blasted, or hand-polished |

| Material Cost: | Medium |

| Alloys & Types: |

Delrin®, or acetal, is a low-friction, high-stiffness plastic material. With a relatively high toughness and minimal elongation, Delrin® boasts excellent dimensional accuracy.

| Mill Lead Time: | *Same day available for small simple parts |

|---|---|

| Color Options: | White, black, brown |

| Material Cost: | Medium |

| Grades: | 150, AF (13% PTFE Filled), 30% Glass Filled |

Garolite G-10 (also known as phenolic and epoxy-grade industrial laminate) is a composite material with a low coefficient of thermal expansion. It does not absorb water and is an excellent insulator, making it useful for electronics applications.

| Mill Lead Time: | As fast as 7 days |

|---|---|

| Color Options: | Green, yellow, black |

| Material Cost: | Medium |

| Alloys & Types: |

High-density polyethylene (HDPE) is a slippery plastic that is often machined into plugs and seals. It is also an excellent electrical insulator as well as being moisture and chemically-resistant.

| Mill Lead Time: | As fast as 14 days |

|---|---|

| Color Options: | White, black |

| Material Cost: | Medium |

| Alloys & Types: |

Nylon is a general purpose plastic material that resists both frictional and chemical wear. Two of the most notable use cases for Nylon are in medical devices and electronics insulation, notably screws and spacers for panel mounted circuit boards.

| Mill Lead Time: | As fast as 7 days |

|---|---|

| Finishing Options: | Dyeing, Painting |

| Material Cost: | Low |

| Alloys & Types: |

In high-stress or high-temperature applications, PEEK is a great lightweight plastic substitute for most soft metals. Additionally, PEEK is resistant to moisture, wear, and chemicals.

| Mill Lead Time: | As fast as 7 days |

|---|---|

| Colors: | Opaque beige |

| Material Cost: | Low |

| Grades: | Standard PEEK, 30% Glass Filled |

Polycarbonate is a transparent thermoplastic with high impact and fracture resistance. It is widely used owing to its eco-friendly processing and recyclability.

| Mill Lead Time: | As fast as 7 days |

|---|---|

| Colors: | Clear, black and glossy |

| Material Cost: | Low |

| Alloys & Types: |

Polypropylene (PP) resists most solvents and chemicals, which makes it a wonderful material to manufacture laboratory equipment and containers for a variety of applications. PP also offers good fatigue strength.

| Mill Lead Time: | As fast as 14 days |

|---|---|

| Colors: | White (semi-clear or opaque) |

| Material Cost: | Low |

| Alloys & Types: |

Polyphenylene Sulfide (PPS) is a high-performance engineering plastic with excellent temperature resistance, dimensional stability, and electrical insulation properties.

| Mill Lead Time: | As fast as 14 days |

|---|---|

| Colors: | Natural (off-white), Black |

| Material Cost: | Medium |

| Alloys & Types: |

Commonly known as Teflon, PTFE resists high temperatures and chemicals/solvents excellently in and is also a great insulator. It is also a very slippery plastic, which makes it a good material for low-friction applications such as bearings.

| Mill Lead Time: | As fast as 7 days |

|---|---|

| Colors: | Black, white (opaque), Natural (off-white) |

| Material Cost: | Medium |

| Alloys & Types: |

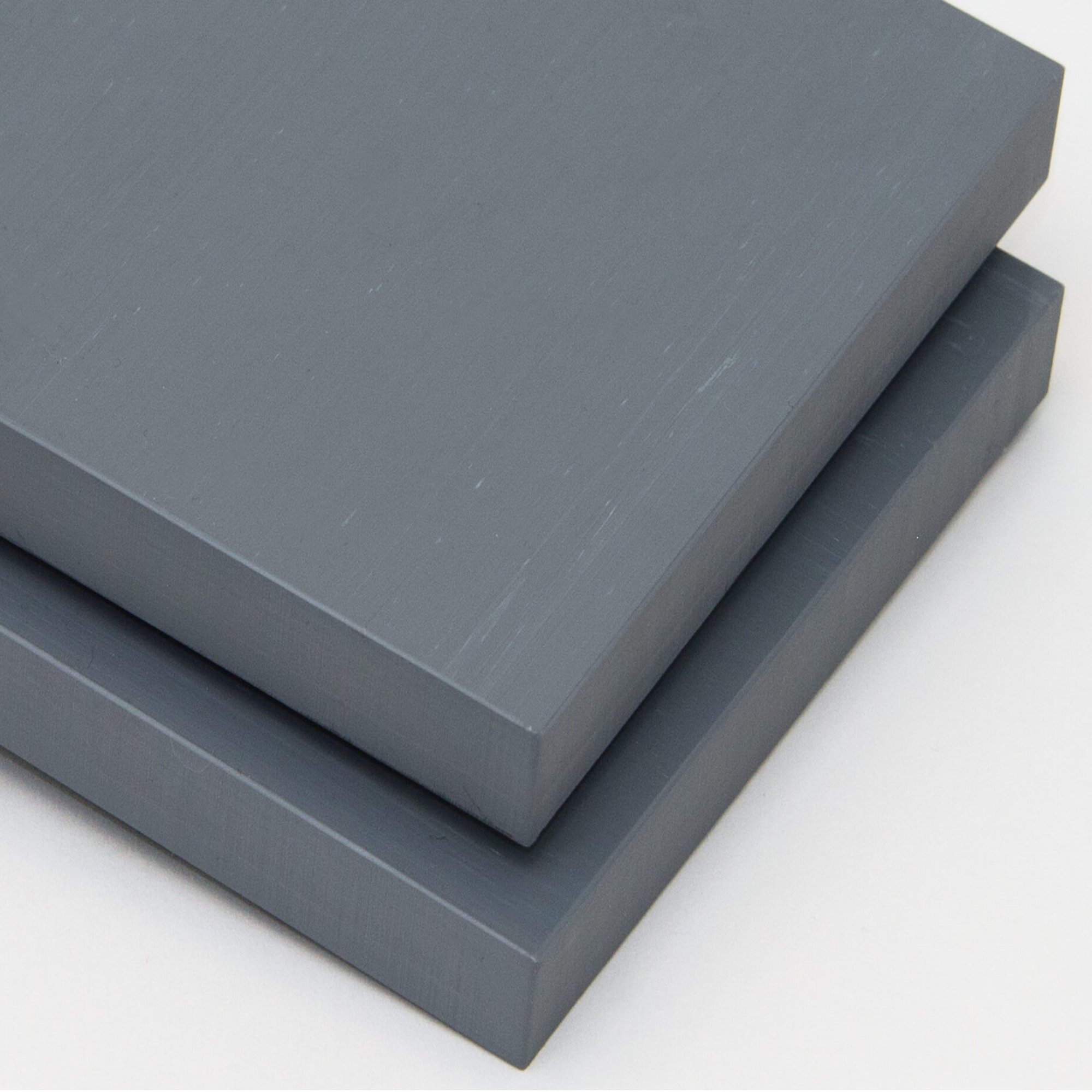

Polyvinyl chloride (PVC) is a rigid material that exhibits high corrosion resistance, high chemical resistance, low moisture absorption, and excellent electrical and insulating properties. It has good dimensional strength and good compressive strength. It is highly machinable to close tolerances making it a great material for a wide range of product fabrication.

| Mill Lead Time: | As fast as 3 days |

|---|---|

| Finishing Options: | Available as-machined, deburred |

| Material Cost: | Medium |

| Alloys & Types: |

Stainless steel is highly resistant to corrosion and rust, making it suitable for situations where a part may be exposed to the elements for long period of time. Stainless steel is also fairly malleable and ductile.

| Mill Lead Time: | As fast as 3 days |

|---|---|

| Finishing Options: | Available as-machined, deburred |

| Material Cost: | High |

| Alloys & Types: |

We offer both alloy and carbon steel options, useful for a variety of applications including fixtures, mounting plates, draft shafts, axles, torsion bars, gears, bolts, studs, shafts, and structural applications.

| Mill Lead Time: | As fast as 7 days |

|---|---|

| Finishing Options: | Black Oxide, ENP, Electropolishing, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing, Zinc Plating, Vibratory Tumbling |

| Material Cost: | Medium |

| Alloys & Types: | 4140, 4130, A514, 4340, 1018 Low Carbon, 1045 Carbon, Zinc-Galvanized Low-Carbon |

Titanium may be selected over other materials such as steel due to its lighter weight and subzero temperature tolerance. Applications include aerospace parts, turbine blades, and medical implants.

| Mill Lead Time: | As fast as 14 days |

|---|---|

| Finishing Options: | Media Blasting, Vibratory Tumbling, Anodizing, Polishing, PVD Coating, Painting |

| Material Cost: | Medium |

| Grade: | Grade 2 & Grade 5 Titanium (Ti-6Al-4V) |

Ultra-High-Molecular-Weight Polyethylene (or UHMW) is a hard plastic with a slippery surface, which resists abrasion and wear. Additionally, it offers high impact strength and is the optimal material for chute/hopper liners and machine guards.

| Mill Lead Time: | As fast as 14 days |

|---|---|

| Colors: | White, black |

| Material Cost: | Medium |

| Alloys & Types: |

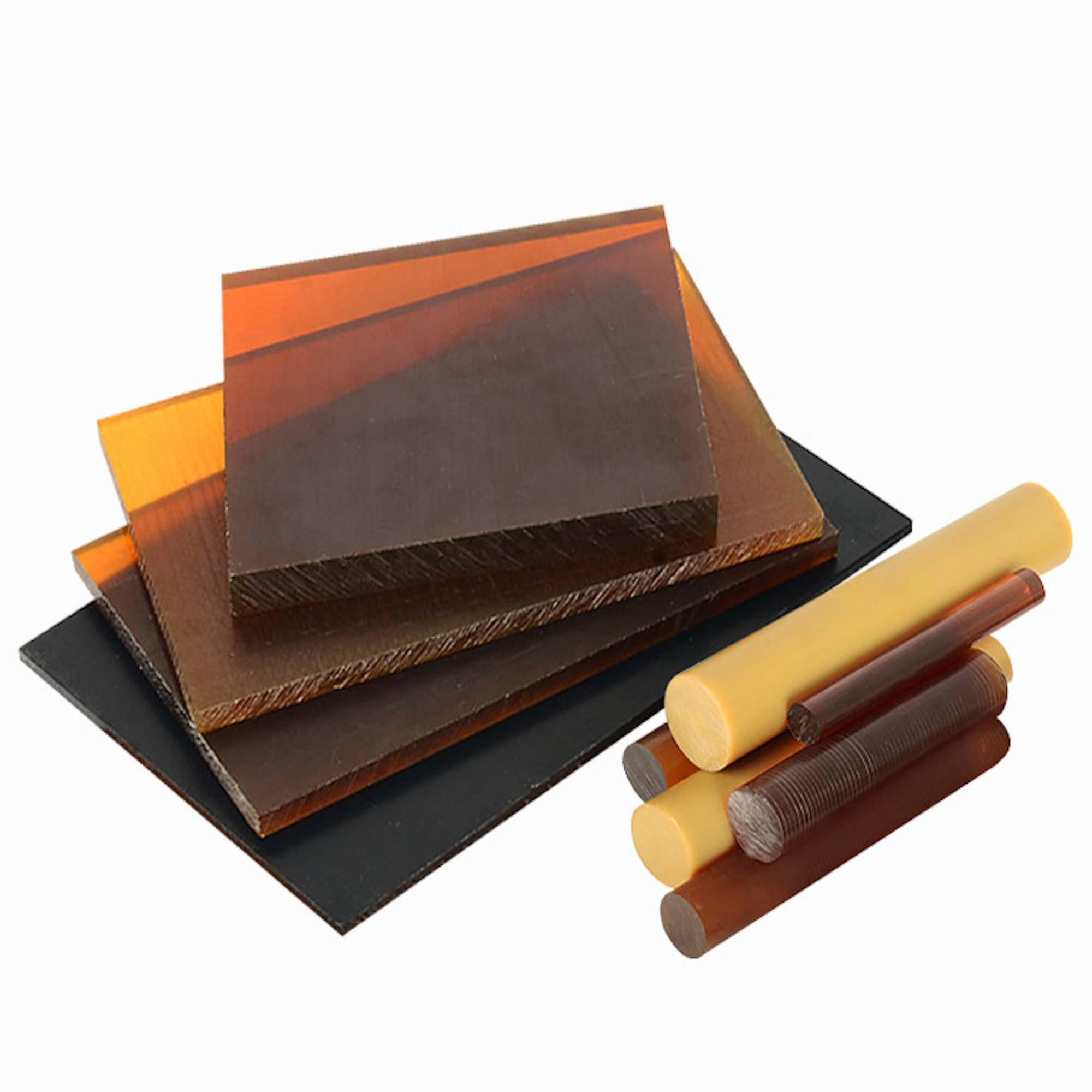

ULTEM 1000 is a translucent amber colored plastic with excellent durability, strength, stiffness and heat resistance. ULTEM 1000 may be selected over Nylon or Delrin® because it has the highest dielectric properties. Common applications include industrial equipment, medical devices and electronics.

| Mill Lead Time: | As fast as 14 days |

|---|---|

| Colors: | Naturally translucent amber color, frosted when machined |

| Material Cost: | Medium |

| Alloys & Types: |

Zinc is used in general engineering for galvanized coatings, in automotive for corrosion protection, and in solar panels for electrical connections, extending the lifespan and efficiency of components.

| Mill Lead Time: | As fast as 14 days |

|---|---|

| Finishing Options: | Vibratory Tumbling, Media Blasting, Electroplating, Powder Coating |

| Material Cost: | Low |

| Alloys & Types: |

*all lead times assuming small simple parts, same day lead time assuming we have in house stock and request is received before 11am.

There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining. By following design-for-manufacturing (DFM) rules, you can get more out of CNC machining's broad capabilities. This can be challenging though, as industry-wide specific standards do not exist. If you are optimizing for costs, check out this guide to designing cost-effective parts for CNC.

We guarantee that our manufacturing partners follow ISO 2768 standards for all CNC machined parts. Parts machined with metal will follow ISO 2768-m (medium) or ISO 2768-f (fine). Parts machined with plastics will follow 2768-m (medium). Geometric tolerances down to ± 0004 in. (0.010 mm) are possible but must be clearly indicated in technical drawings. We can achieve tighter tolerances on shafts with up to H7 fits with manual quoting and on occasion tighter.

Computer Numerical Control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. This is in contrast to machines that are manually controlled by hand wheels or levers, or mechanically automated by cams alone. Both a CNC router and mill create parts by removing material from a piece, also known as subtractive manufacturing. This process is different from CNC machines, such as 3D printers, that add materials to create a shape or part. The part’s mechanical dimensions are defined using computer-aided design (CAD) software and then translated into manufacturing directives by computer-aided manufacturing (CAM) software. The resulting directives are transformed (by “post processor” software) into the specific commands necessary for a particular machine to produce the component and then are loaded into the CNC machine.

Our CNC mill machine is a 3-axis Haas Mill. It offers better cutting angles and a wider range of axes since it moves both the solid material and spindle heads. For instance: The cutting tool handles the X and Y axes The table controls the Z-axis Over five additional axes can be added These machines have RPMs between 60,000 to 80,000 but offer higher torques for heavy-duty projects. It uses an end mill as the cutting tool, which comes in different configurations and shapes. Examples include flat end mills and ball end mills that create different quality scalloping.

Call Us - (805) 987-6217 - Email Us - contact@eliteeng.com - fill out the Contact Form page- here...